Home >Metal Products >Custom Parts > High precision chunk parts roll rachis MIM process manufacturer

Product Description

Brand name | OEM & ODM |

Product type | Printer head gear other MIM process products MIM spare parts manuafcturer |

Product Model | HBMIM-001B |

Material | Stainless steel 304,316L,17-4PH,TI |

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | ≤200g |

Forming Method | Metal Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Steel |

Hardness | 30-35HRC |

Application | Other MIM mechnical industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 25-30 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

There are various types of MIM raw material with it own special characteristics to choose from, it could help to meet your requirements from carbon iron to stainless steel.

Made as customers' detailed drawings & samples.

Used for some types of machines.

♦ Machining free (achieve sharp angle of R ≤ 0.1mm; Depth of Parallelism ≤ 0.02; Ra ≤ 1.6μm; tolerance in ±0.025mm-±0.05mm)

♦ Excellent geometrically complexity ( achieve a hole of 0.4mm, thin wall of 1mm )

♦ More than 98% of material utilization rate

♦ Part-to-part uniformity

♦ More than 95% of theoretical density, and its performance is comparable with forging parts.

Precision MIM parts

High purity, low inclusion MIM parts

Irregular and spherical powder shape

Low oxygen content MIM parts

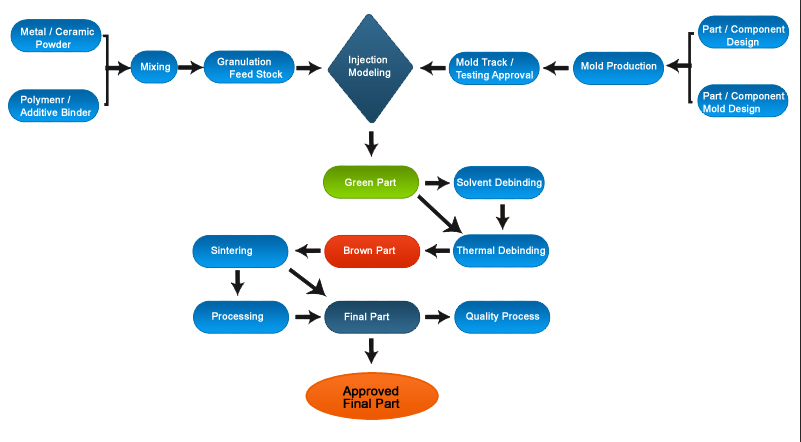

The MIM process combines the design flexibility of plastic injection molding with the strength and integrity of wronght metals to offer cost effective solutions for highly complex part geometries.

The MIM process is typically explained as four unique processing

steps (compounding, molding, debinding and sintering) to produce

a final part that may or may not need final finishing operations

It is a net-shape process for the manufacturing of high volume high precision components for use in a diverse range of industries. MIM parts can now be found in all areas of life, from our cars and trucks to watches, dental braces, door safe lock, mobile phones, IT equipment, DIY tools and much more.

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.