Home >Metal Products >MIM Products >Auto Parts > Motorcycle steel MIM Sprocket parts

Product Description

Precision MIM parts High purity, low inclusion MIM parts Irregular and spherical powder shape Low oxygen content MIM parts Powder Injection Molding (PIM), which encompasses Metal Injection Molding (MIM) ), is a new type manufacture technology which combines plastic injection molding process with powder metallurgy process. It is a net-shape process for the manufacturing of high volume high precision components for use in a diverse range of industries. MIM parts can now be found in all areas of life, from our cars and trucks to watches, dental braces, mobile phones, IT equipment, DIY tools and much more.

Engineered for Maximum Value

MIM technology provides the unique ability to produce highly complex components that cannot be achieved economically by any other process.

Harber Industrial works closely with you on design, materials and finish requirements to extract maximum value from the MIM process. Our extensive in-house capabilities in machining, heat-treating and surface finishing provide a way to manage total program cost.

Powder Injection Molding (PIM), which encompasses Metal Injection Molding (MIM) ), is a new type manufacture technology which combines plastic injection molding process with powder metallurgy process. It is a net-shape process for the manufacturing of high volume high precision components for use in a diverse range of industries. MIM parts can now be found in all areas of life, from our cars and trucks to watches, dental braces, mobile phones, IT equipment, DIY tools and much more.

Adaptable Production Demands

The wide range of applications for industrial products demands a supplier who is capable of meeting both small and large batch-manufacturing requirements.

Brand name | OEM & ODM |

Product type | MIM Car Auto Parts |

Product Model | HBMIM-001B |

Material | Stainless steel 304,316L,17-4PH,TI |

Post-Sintering | Polishing,Wire-drawing,Sandblasting,Plating,Coated,etc. |

Size | Custom |

Tolerance | 10mm±(0.02-0.04)mm |

Weight | ≤200g |

Forming Method | Metal Injection Molding |

Sintering method | Solid phase sintering |

Sintering environment | Vacuum |

Mold material | Steel |

Application | Lock industry |

Shape | Custom |

OEM | Accept |

QC system | 100% inspection before shipment |

Payment terms | T/T at sight, Paypal, Western Union,etc. |

Lead time | 25-30 working days |

Supply capability | 500000 Piece Per Month |

Packaging | PP bag / Anti-static film / anti-static plastic disc |

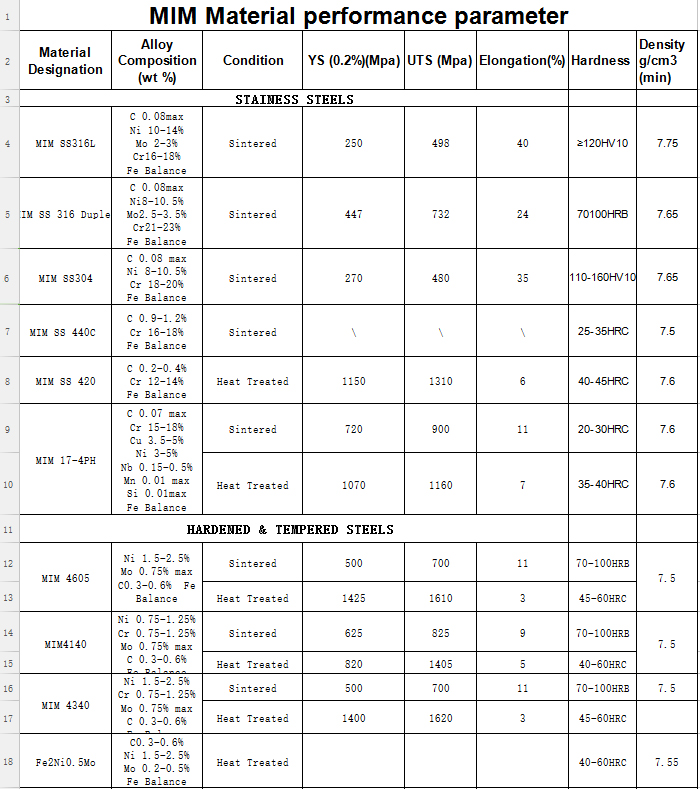

Materials for Diverse Applications

We provides a wealth of material options that allow our customers to achieve high performance in their products.

MIM Industrial Product Solutions

Door hardware – Lock housings, cylinders, carriers, pins

Hand and power tools – Handles, bits, keyless chucks, blade clamps, pawls, ratchet mechanisms

Electronics – Sensor housings, fiber optic connectors, microwave packages, heatsinks

Hydraulics – Valve spools, housings, lavatory fixtures

Fasteners and Hardware – Aerospace

Plumbing – Valve spools, faucet hardware

Safety – Fall protection mechanisms

Oil & Gas – Valve components for high corrosion applications

Products Range:

| MIM Processing | Molding, Injection, Debinding,Sintering ,Second Operation |

| Applied Software | PRO/E, Auto CAD, Solid Works, UG, CAD/CAM/CAE |

| Material | Iron-based Alloy,Stainless Steel,Tungsten Alloy,Carbide Alloy,Tool Steel , Fine Ceramic , Titanium Alloy |

| Surface Finish | Grinding,Brush,Polishing,PVD,Zinc/Nickel/Chrome/Gold Plating, Sand Blasting& etc. |

| Tolerance Precision | +/-0.005~0.02mm, can also be customized. |

| Dimension | As per customers' request |

| Part Color | Silver, Red, Blue, Gold, Oliver, Black, White & etc. |

| Samples | Acceptable |

| Quality System | 100% inspection before shipment |

| Lead Time | Based on the quantity of order (Usually 45 days) |

| Packing | Plastic tray, plastic bag and Carton, full consider of practical situation |

| Shipping | By sea, By air, By DHL, UPS, TNT & etc. |

| Shipment Port | All products SGS,CTI and RoHs approved, All material REACH approved. |

Used for Auto, car motor with your specialize requirements.

Precision MIM parts

High purity, low inclusion MIM parts

Irregular and spherical powder shape

Low oxygen content MIM parts

Powder Injection Molding (PIM), which encompasses Metal Injection Molding (MIM) ), is a new type manufacture technology which combines plastic injection molding process with powder metallurgy process. It is a net-shape process for the manufacturing of high volume high precision components for use in a diverse range of industries. MIM parts can now be found in all areas of life, from our cars and trucks to watches, dental braces, mobile phones, IT equipment, DIY tools and much more.

Why Choose MIM?

♦ Machining free (achieve sharp angle of R ≤ 0.1mm; Depth of Parallelism ≤ 0.02; Ra ≤ 1.6μm; tolerance in ±0.025mm-±0.05mm)

♦ Excellent geometrically complexity ( achieve a hole of 0.4mm, thin wall of 1mm )

♦ More than 98% of material utilization rate

♦ Part-to-part uniformity

♦ More than 95% of theoretical density, and its performance is comparable with forging parts.

When it comes to automotive metal injection molding you will need high-precision parts for the best performance possible. With our extensive metal injection molding service and secondary process options, we are capable of manufacturing the best mim parts for various automobile brands.

High precise

With our precise moulding methods, you could be assured that all your automotive metal components are of the best quality possible. Harber makes it a priority that all the dimensions of your metal car parts are as precise as possible.

Short lead time

One of the key advantages of our metal injection moulding technology is our very short lead time. Just give us the exact specifications and dimensions of your auto metal parts, and we could produce the metal components for you in record time.

Instant quote

If you are interested in availing some of our metal injection moulding services, we are more than capable of providing you with an instant quote. This helps streamline the process, and makes all of our transactions more efficient.

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.